4.1. Modeling Systems of Linear Equations#

4.1.1. Learning Objectives#

After studying this notebook, completing the activities, and asking questions in class, you should be able to:

Create a mathematical model on paper for a system of linear equations.

Implement the model in python to solve for the solutions and interpret the results.

import numpy as np

4.1.2. Introduction#

I would bet you can think of at least five classes where you solved one or more algebraic equations as part of a scientific or engineering calculation. In this class, we will learn how to solve algebraic equations in Python for several fundamental chemical engineering problems.

Home Activity

List out the problem solving steps you learned in CBE 20255 for mass and energy balance analysis of chemical processes.

We will now practice these problem solving steps.

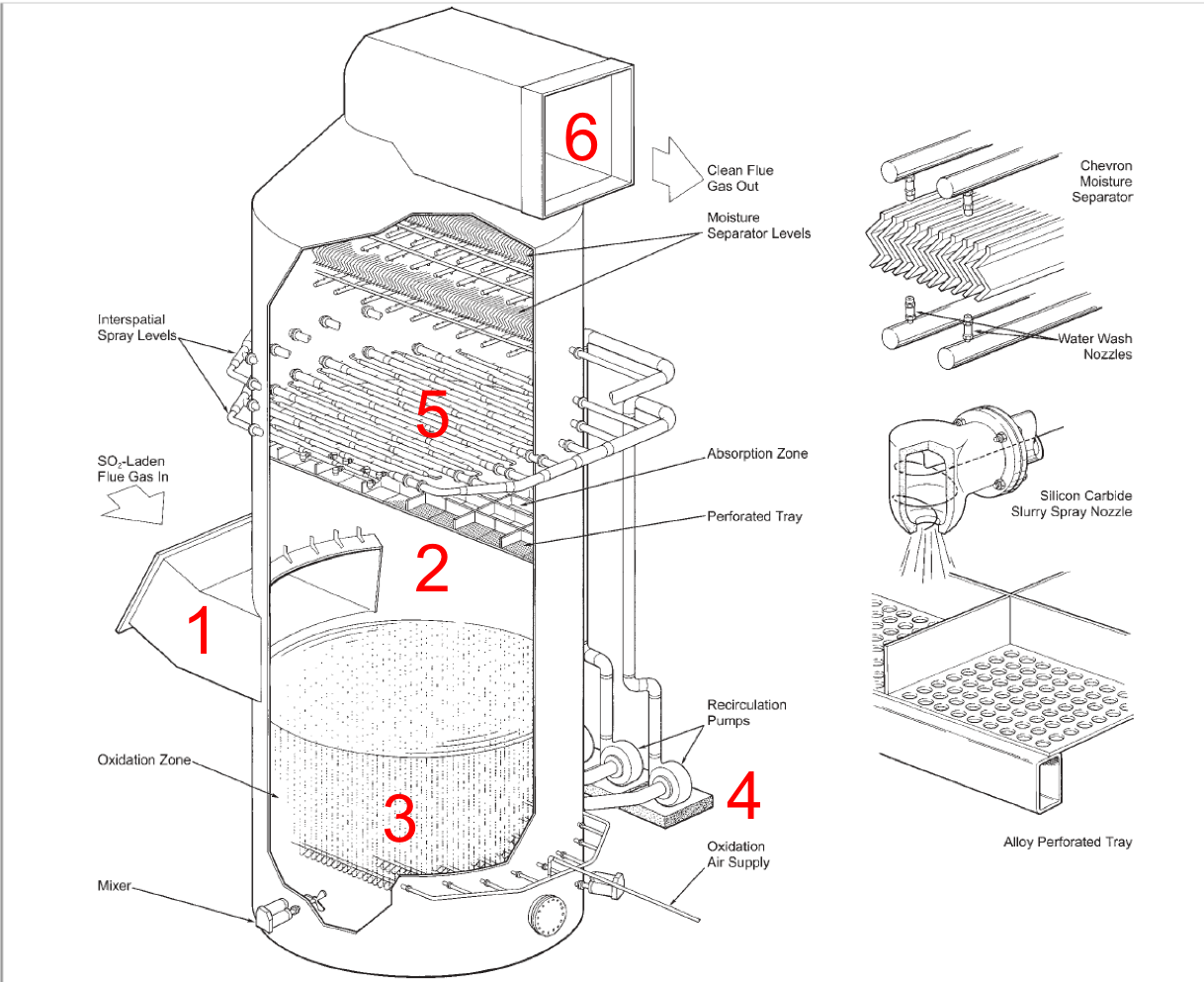

4.1.3. Environmental Controls for a Power Plant#

In power plants, it is essential to remove pollutants such as SO\(_x\) from the flue gas before it is vented to the atmosphere. This is commonly done with a wet flue gas desulfuriziation (WFGD) system in a coal power plant. The main idea is to react calcium carbonate, calcium hydroxide, or magnesium hydroxide with SO\(_2\) to form calcium or magnesium sulfate. In fact, calcium sulfate is commonly known as gypsum, which can be sold as an ingredient to make drywall. While SO\(_x\) refers to many components, we will focus our analysis on just SO\(_2\).

Here are the main chemical reactions:

CaCO\(_{3\mathrm{(s)}}\) + SO\(_{2\mathrm{(g)}}\) \(\rightarrow\) CaSO\(_{3{(s)}}\) + CO\(_{2\mathrm{(g)}}\)

or

Ca(OH)\(_{2\mathrm{(s)}}\) + SO\(_{2\mathrm{(g)}}\) \(\rightarrow\) CaSO\(_\mathrm{3(s)}\) + H\(_{2}\)O\(_{\mathrm{(l)}}\)

or

Mg(OH)\(_{2\mathrm{(s)}}\) + SO\(_{2\mathrm{(g)}}\) \(\rightarrow\) MgSO\(_\mathrm{3(s)}\) + H\(_{2}\)O\(_{\mathrm{(l)}}\)

Below is an illustration of a wet FGD unit (adapted from Babcock and Wilcox Company, Steam: Its Generation and Uses, 2005):

Feed. Flue gas with SO\(_x\) enters the FGD.

Absorption Zone. As flue gas moves upward through the unit, it comes in contact with a slurry. SO\(_x\) moves from the vapor phase (flue gas) to the liquid phase (slurry). Chemical engineers call this process absorption.

Oxidation Zone. The SO\(_x\) reacts to form a solid product via the chemical reactions stated above. It is reasonable to assume these reactions go to completition and all of the SO\(_x\) in the oxidation zone reacts.

Pump. The slurry mixture is pumped to the top of the absorber.

Sprayer. The slurry mixture is spray at the top of the absorber to ensure even distribution throughout the column.

Effluent. Cleaned flue gas leaves the absorber.

The wet FGD is an excellent example for our class because it foreshadows then entire CBE undergraduate curriculum. For the next 5 semesters, you will develop the technical background to fully analyze a WFGD and similar systems:

Thermodynamics (CBE 20260): Solubility of SO\(_x\) in the water-slurry

Transport (CBE 30355, 30356): Rate of mass and energy transfer bewteen the vapor and liquid phases

Phase Equilibrium and Separations (CBE 30370): Detailed equipment design including sizing

Process Control (CBE 30338): Dynamic operation (i.e., NOT at steady-state)

Reaction Engineering (CBE 40445): Oxidation reaction to create byproduct

Process Design (CBE 40448): Integration of a system (e.g., WFGD) into a larger process (e.g., power plant)

4.1.4. Determine Additional Data and Analysis Goal#

Let’s use your background from CBE 20255 (Introduction to Chemical Engineering) to analyze this system.

Feed Specifications

Species |

Mass Flowrate |

Mass Fraction |

|---|---|---|

\(H_20\) |

\(240,000\) lb/h |

\(4.3\) % |

\(SO_2\) |

\(34,900\) lb/h |

\(0.6\) % |

\(HCl\) |

\(458\) lb/h |

\(8.0\) x \(10^{-3}\) % |

Air/other |

\(5,245,600\) lb/h |

\(95.0\) % |

Table 1: Flue gas flow rate and compositions before treatment for a 500 MW coal-fired power plant (Babcock and Wilcox Company, Steam: Its Generation and Uses, 2005).

For reference, the Notre Dame power plant has a maximum electricity output capacity of 28.6 MW. It also co-generates steam and chilled water, so direct comparison is difficult. It is about 20 times smaller. Notre Dame phased out coal use in the power plant in 2020.

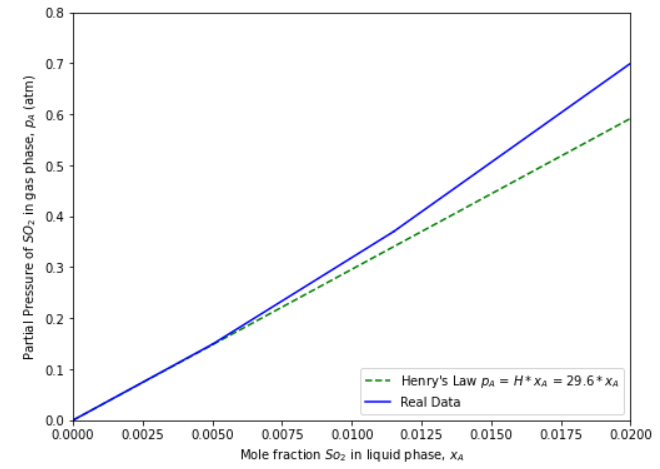

Equilibrium Information

For a first approximation, we can assume:

Virtually no air dissolves in the slurry

Virtually no water evaporates from the slurry into the flue gas

This means we only need to worry about the solubility of the SO\(_x\) that dissolves into the slurry. As another assumption, we will model the slurry as water. In CBE 20255, you may have learned about Henry’s Law, a simple correlation for solubility.

Figure 2: Henry’s law for SO\(_2\) solubility in water (C. J. Geankoplis, Transport Processes and Separation Process Principles: Includes Unit Operations, 2003).

Design/Analysis Goal

We want to compute the required flow rate of water to achieve 98% removal of SO\(_2\) for a large (500 MW) power plant.

4.1.5. Draw a Picture#

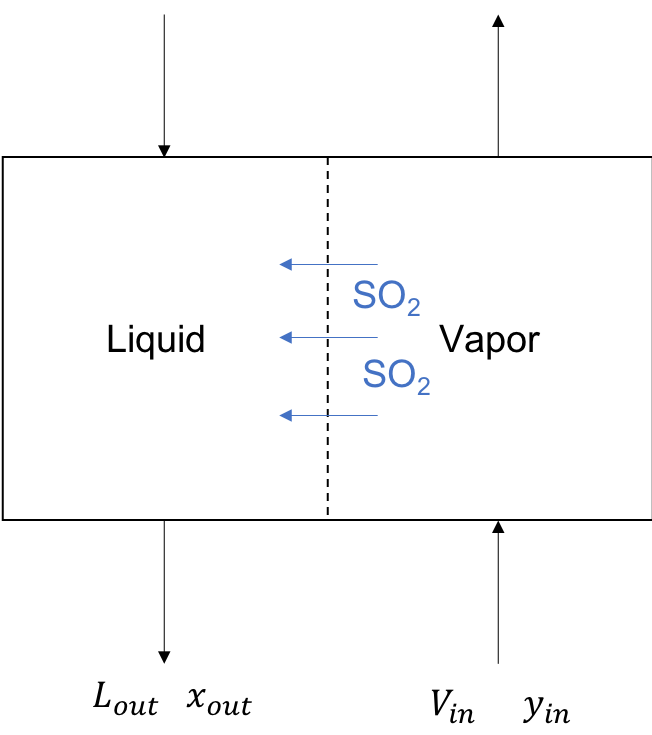

Next, let’s draw a picture of the system.

In this simplified picture, the vapor stream (flue gas) enters at the bottom right and the liquid stream (slurry) enters at the top left. We assume only SO\(_2\) moves from the vapor to the liquid. In this picture, \(L\) and \(V\) are total stream flowrates. \(x\) and \(y\) are the mole fraction of \(SO_2\).

Home Activity

Copy this picture onto paper. Then identify the quantities we already know from the previous information.

4.1.6. State Assumptions#

With enough assumptions, we can perform quick “back of the envelope” design calculations for the SO\(_2\) absorber using mostly skills you learned in CBE 20255.

Home Activity

Make a list of at least three assumptions we need to compute the required liquid flowrate to achieve 98% SO\(_2\) removal.

4.1.7. Mathematical Model#

With these assumptions, we can propose a mathematical model for the absorber:

Equation A: \(V_{in} + L_{in} = V_{out} + L_{out}\)

Equation B: \(y_{out} = K x_{out}\)

Equation C: \(V_{in} y_{in} + L_{in} x_{in} = V_{out} y_{out} + L_{out} x_{out}\)

Equation D: \(y_{out} = (1 - 0.98) y_{in}\)

Home Activity

Identify the name for each equation from the list of choices below. Record your answer in the dictionary eqn_names. Use ‘A’, ‘B’, ‘C’, and ‘D’ as the keys and 1, 2, 3, 4, 5, 6, 7, or 8 as the values.

Choices for equation names:

Overall mass (mole) balance

SO\(_2\) component mass (mole) balance

Water component mass (mole) balance

Air component mass (mole) balance

Energy balance

Entropy balance

Design goal: 98% SO\(_2\) removal

SO\(_2\) equilibrium (Henry’s Law)

eqn_names = {'A': 0, 'B':0, 'C':0, 'D':0}

# Add your solution here

# Removed autograder test. You may delete this cell.

4.1.8. Degree of Freedom Analysis#

The next step after writing a model is to perform degree of freedom analysis.

Home Activity

Perform degree of freedom analysis. On paper, identify the number of unknowns (variables) and the number of equations. Then determine the number of additional specifications or equations needed to complete the design calculations.

4.1.9. Revised Model#

Let’s make two additional assumptions:

The slurry entering the top of the absorber contains no water, i.e., \(x_{in} = 0\)

The flowrate of liquid in the absorber is approximately constant, i.e., \(L_{in} = L_{out}\)

Home Activity

Provide a physical justification for \(L_{in} = L_{out}\). Why is this a reasonable assumption? Write a few sentences.

Home Activity

Does \(L_{in} = L_{out}\) imply \(V_{in} = V_{out}\)? Explain in a few sentences.

4.1.10. Calculations#

We now have a mathematical model with zero degrees of freedom. But before we use Python, let’s first manipulate the model on paper.

Home Activity

Using the mathematical model and algebra, derive the following formula for the liquid flowrate \(L\).

We can now use Python as a calculator to compute \(L\). First, we will copy the given data.

### Step 1. Define Given Data

# Feed flowrate of SO2 in [lb / hr]

m_SO2 = 34900

# Feed flowrate of air in [lb / hr]

m_air = 5245600

# Molecular weights [g / mol]

mw_SO2 = 64.066

mw_air = 28.97

mw_water = 18.01528

# Removal efficieny (design goal)

eff = 0.98

# Equilibrium coefficient [mol frac SO2 in vapor / mol frac SO2 in liquid ]

# Taken from plot with Henry's law fit

K = 29.6

# Composition of SO2 in liquid feed in [mol frac]

xin = 0.0

How important is it to include SO\(_2\) when computing \(V\)?

### Step 2. Convert to molar basis

# Vapor flowrate in [lb-mol / hr]

# How much does neglecting SO2 in feed change the final answer?

V = m_air / mw_air + m_SO2 / mw_SO2;

Valt = m_air / mw_air

print("Flowrate if SO2 is considered",V," lb-mol / hr")

print("Flowrate if SO2 is neglected",Valt," lb-mol/hr")

print("Relative difference: ",(V-Valt)/V*100,"%")

Flowrate if SO2 is considered 181614.8232145955 lb-mol / hr

Flowrate if SO2 is neglected 181070.0724887815 lb-mol/hr

Relative difference: 0.29994838316161015 %

Not very important! We can live with a 0.3% error.

Home Activity

Compute the mole fraction of SO\(_2\) in the vapor inlet. Store your answer in yin

# SO2 in flue gas feed

# Add your solution here

print("yin = ",yin*100,"mol %")

# Removed autograder test. You may delete this cell.

Home Activity

Compute the mole fraction of SO\(_2\) in the vapor outlet if the unit achieves with 98% SO\(_2\) removal. Store your answer in yout.

### Step 3. Compute vapor outlet composition

# SO2 in vapor outlet in [mol frac]

# Add your solution here

print("yout = ",yout*100,"mol %")

# Removed autograder test. You may delete this cell.

Finally, we can apply the formula we derived. We will calculate from lb-mol/hr to lb/hr, because, who really has intuition in lb-mol/hr?

Home Activity

Compute the liquid flowrate. Store your answer in L with units lb-mol/hr and L_lb with units lb/hr.

### Step 4. Apply formulas we derived with direct substitution

# Liquid outlet composition in [mol frac]

xout = yout / K

print("xout = ",xout*100,"mol %")

# Liquid flowrate in lb-mol/hr

# Add your solution here

print("L = ",L,"lb-mol/hr")

# Liquid flowrate in lb/hr

# Add your solution here

print("L = ",L_lb/1E6,"millon lb/hr of water")

# Removed autograder test. You may delete this cell.

I, for one, do not have a good intuition for the size of 1 millions pounds of water. Let’s convert into Olympic swimming pools!

### Step 5. Convert and interpret

# How much water does an Olympic swimming pool hold (in [lb])?

swimming_pool = 5.5E6;

# Convert to swimming pools

L_pool = L_lb / swimming_pool

print("L = ",L_pool,"Olympic swimming pools per hour")

Class Activity

Compare your home activity results with a partner. Create a list of questions to discuss as a class.

4.1.11. Final Result and Discussion#

This is the final step of our analysis: interpret the results.

Based on these calculates, we approximate a naive WFGD system would require 870 Olympic swimming pools per hour of fresh water to treat the flue gas in the 500 MW power plant.

Class Activity

As a class, complete the following: (i) This result is reasonable/unreasonable because… (ii) To refine these calculations, we could…

4.1.12. FGD Revisited with Linear Algebra#

Earlier in this notebook we practiced modeling and problem solving steps from CBE 20255. We performed direct substitution on paper and used Python as a simple calculator. Is there an alternate way to attack this problem? You bet!

4.1.13. Rewrite Model as a Linear System#

If we write the model in matrix form, we can use tools from linear algebra to solve the equations simultaneously.

Class Activity

Rewrite the mathematical model as a linear system of equations.

4.1.14. Solve Linear System with Python#

Now let’s see how to solve a linear system of equations in Python. Notice, we need to choose a value of \(L\).

# Assemble linear system

A = np.array([[L, V],[K, -1]])

print("A = \n",A)

b = np.array([L*xin + V*yin, 0])

print("\nb = \n",b)

# Solve linear system

z = np.linalg.solve(A,b)

print("\nz = \n",z)

A =

[[ 2.63414140e+08 1.81614823e+05]

[ 2.96000000e+01 -1.00000000e+00]]

b =

[544.75072581 0. ]

z =

[2.02667826e-06 5.99896766e-05]

4.1.15. Perform Sensitivity Analysis to Determine L#

How can we use our model to calculate \(L\) for the design goal? We can perform sensitivity analysis and plot our results. Consider the following steps:

Loop over a range of L values. For each value of L:

Solve the linear system

Record yout

Plot L vs yout on a semilog plot.

Add the design target for yout to the plot.

Class Activity

Write pseudocode to perform the following steps.

# Create values of L to try that are log spaced

print(np.logspace(6,10,10))

[1.00000000e+06 2.78255940e+06 7.74263683e+06 2.15443469e+07

5.99484250e+07 1.66810054e+08 4.64158883e+08 1.29154967e+09

3.59381366e+09 1.00000000e+10]

import matplotlib.pyplot as plt

%matplotlib inline

# define values from 1E6 to 1E10 to try for L

Ltry = np.logspace(6,10,10)

# allocate array to store results

yout_store = np.zeros(len(Ltry))

count = 0

# Loop through values in Ltry

# Add your solution here

# Solve linear system

# Add your solution here

# Store value

# Add your solution here

# increment counter

# Add your solution here

# convert L to swimming pool units

Ltry2 = Ltry * mw_water / swimming_pool

# create plot

# Add your solution here