5.2. Linear Blending Problems#

This notebook introduces material blending problems and outlines a multi-step procedure for developing and solving models using Pyomo.

# install Pyomo and solvers for Google Colab

import sys

on_colab = "google.colab" in sys.modules

if on_colab:

!wget "https://raw.githubusercontent.com/IDAES/idaes-pse/main/scripts/colab_helper.py"

import colab_helper

colab_helper.install_idaes()

colab_helper.install_ipopt()

# Set default font sizes for plots

import matplotlib.pyplot as plt

plt.rcParams['font.size'] = 18

plt.rcParams['lines.linewidth'] = 3.0

# Alternately, you can set these individually

#plt.rcParams['axes.labelsize'] = 18

#plt.rcParams['axes.titlesize'] = 18

#plt.rcParams['xtick.labelsize'] = 18

#plt.rcParams['ytick.labelsize'] = 18

#plt.rcParams['legend.fontsize'] = 18

5.2.1. Learning Goals#

Linear Blending problems

Frequently encountered in material blending

Models generally consist of linear mixing rules and mass/material balances

Decision variables are indexed by a set of raw materials

Further practice with key elements of modeling for optimization

pyo.ConcreteModel()to create a new instancce of an optimization modelpyo.Set()to create an index used to index decision variablespyo.Var()to create an optimization decision variablemodel.Comstraint()to decorate (tag) the output of a function as an optimization constraintmodel.Objective()to decorate (tag) the output of a function as an optimization objective

Modeling and solving linear blending problems in CVXPY

Step 1. Coding problem data. Nested dictionaries or Pandas dataframes.

Step 2. Create index set. Use .keys() with nested dictionaries, or .index with Pandas dataframes.

Step 3. Create a dictionary of decision variables. Add any pertinent qualifiers or constraints for individual variables such as lower and upper bounds, non-negativity, variable names.

Step 4. Create an expression defining the problem objective.

Step 5. Create a one or more lists of problem constraints.

Step 6. Create the problem object from the objectives and constraints.

Step 7. Solve and display the solution.

5.2.2. Problem Statement (Jenchura, 2017)#

A brewery receives an order for 100 gallons that is at least 4% ABV (alchohol by volume) beer. The brewery has on hand beer A that is 4.5% ABV and costs $0.32 per gallon to make, and beer B that is 3.7% ABV and costs $0.25 per gallon. Water (W) can also be used as a blending agent at a cost of $0.05 per gallon. Find the minimum cost blend of A, B, and W that meets the customer requirements.

5.2.3. Analysis#

Before going futher, carefully read the problem description with the following questions in mind.

What are the decision variables?

What is the objective?

What are the constraints?

5.2.3.1. Decision variables#

The decision variables for this problem are the amounts of blending stocks “A”, “B”, and “W” to included in the final batch. We can define a set of blending stocks \(S\), and non-negative decision variables \(x_s\) that are indexed by the components in \(S\) that denote the amount of \(s\) included in the final batch.

5.2.3.2. Objective#

If we designate the price of blending stock \(s \in S\) as \(P_s\), the cost is

The objective is to minimize cost.

5.2.3.3. Constraints#

5.2.3.3.1. Order Volume#

Let \(V = 100\) represent the desired volume of product and assume ideal mixing. Then

5.2.3.3.2. Alcohol by Volume#

Let \(C_s\) denote the volume fraction of alcohol in blending stock \(s\). Assuming ideal mixing, the total volume of of alchohol in the final product be

If \(\bar{C}\) denotes the required average concentration, then

Which is not linear in the decision variables. If at all possible, linear constraints are much preferred because (1) they enable the use of LP solvers, and (2) then tend to avoid problems that can arise with division by zero and other issues.

There are other ways to write composition constraints, but this one is preferred because it isolates the product quality parameter, \(\bar{C}\), in a single constraint. This constraint has “one job to do”.

5.2.4. Solving optimization problems with Pyomo#

5.2.4.1. Step 1. Coding Problem Data as a Pandas DataFrame#

The first step is to represent the problem data in a generic manner that could be extended to include additional blending components. Here we use a Pandas dataframe of raw materials, each row representing a unique blending agent, and columns containing attributes of the blending components. This is consistent with “Tidy Data” principles.

import pandas as pd

data = pd.DataFrame([

['A', 0.045, 0.32],

['B', 0.037, 0.25],

['W', 0.000, 0.05]],

columns = ['blending stock', 'Concentration', 'Price']

)

data.set_index('blending stock', inplace=True)

display(data)

| Concentration | Price | |

|---|---|---|

| blending stock | ||

| A | 0.045 | 0.32 |

| B | 0.037 | 0.25 |

| W | 0.000 | 0.05 |

5.2.4.2. Step 2. Creating a model instance#

import numpy as np

import pyomo.environ as pyo

bm = pyo.ConcreteModel('Blending Model')

5.2.4.3. Step 3. Identifying index sets#

The objectives and constraints encountered in optimization problems often include sums over a set of objects. In the case, we will need to create sums over the set of blending stocks. We will use these index sets to create decision variables and to express the sums that appear in the objective and constraints

data.index

Index(['A', 'B', 'W'], dtype='object', name='blending stock')

bm.S = pyo.Set(initialize=data.index)

for s in bm.S:

print(s)

A

B

W

5.2.4.4. Step 4. Create decision variables#

Most real-world applications of optimization technologies involve many decision variables and constraints. It would be impractical to create unique identifiers for literally thousands of variables. For this reason, the pyo.Var() and other objects can create indexed sets of variables and constraints. Here is how it is done for the blending problem.

bm.x = pyo.Var(bm.S, domain=pyo.NonNegativeReals)

5.2.4.5. Step 4. Objective Function#

If we let subscript \(d\) denote a blending d from the set of blending components \(C\), and denote the volume of \(c\) used in the blend as \(x_c\), the cost of the blend is

where \(P_s\) is the price per unit volume of \(s\). Using the Python data dictionary defined above, the price \(P_s\) is given by data[s, 'Price']

@bm.Objective(sense=pyo.minimize)

def cost(bm):

return sum(bm.x[s] * data.loc[s, "Price"] for s in bm.S)

bm.cost.pprint()

cost : Size=1, Index=None, Active=True

Key : Active : Sense : Expression

None : True : minimize : 0.32*x[A] + 0.25*x[B] + 0.05*x[W]

5.2.4.6. Step 5. Constraints#

5.2.4.6.1. Volume Constraint#

The customer requirement is produce a total volume \(V\). Assuming ideal solutions, the constraint is given by

where \(x_s\) denotes the volume of blending stock \(s\) used in the blend.

V = 100

@bm.Constraint()

def volume(bm):

return sum(bm.x[s] for s in bm.S) == V

bm.volume.pprint()

volume : Size=1, Index=None, Active=True

Key : Lower : Body : Upper : Active

None : 100.0 : x[A] + x[B] + x[W] : 100.0 : True

5.2.4.6.2. Composition Constraint#

C_lb = 0.04

@bm.Constraint()

def composition(bm):

return sum(bm.x[s]*(data.loc[s, "Concentration"] - C_lb) for s in bm.S) >= 0

bm.composition.pprint()

composition : Size=1, Index=None, Active=True

Key : Lower : Body : Upper : Active

None : 0.0 : 0.0049999999999999975*x[A] - 0.0030000000000000027*x[B] - 0.04*x[W] : +Inf : True

5.2.4.7. Step 6. Solve#

bm.pprint()

1 Set Declarations

S : Size=1, Index=None, Ordered=Insertion

Key : Dimen : Domain : Size : Members

None : 1 : Any : 3 : {'A', 'B', 'W'}

1 Var Declarations

x : Size=3, Index=S

Key : Lower : Value : Upper : Fixed : Stale : Domain

A : 0 : None : None : False : True : NonNegativeReals

B : 0 : None : None : False : True : NonNegativeReals

W : 0 : None : None : False : True : NonNegativeReals

1 Objective Declarations

cost : Size=1, Index=None, Active=True

Key : Active : Sense : Expression

None : True : minimize : 0.32*x[A] + 0.25*x[B] + 0.05*x[W]

2 Constraint Declarations

composition : Size=1, Index=None, Active=True

Key : Lower : Body : Upper : Active

None : 0.0 : 0.0049999999999999975*x[A] - 0.0030000000000000027*x[B] - 0.04*x[W] : +Inf : True

volume : Size=1, Index=None, Active=True

Key : Lower : Body : Upper : Active

None : 100.0 : x[A] + x[B] + x[W] : 100.0 : True

5 Declarations: S x cost volume composition

#solver = pyo.SolverFactory('glpk')

solver = pyo.SolverFactory('cbc')

solver.solve(bm, tee=True).write()

Welcome to the CBC MILP Solver

Version: 2.10.10

Build Date: Jun 7 2023

command line - /Users/adowling/.idaes/bin/cbc -printingOptions all -import /var/folders/3w/vr4xmyqs451dg23xk88pqcg00000gq/T/tmpdiistyea.pyomo.lp -stat=1 -solve -solu /var/folders/3w/vr4xmyqs451dg23xk88pqcg00000gq/T/tmpdiistyea.pyomo.soln (default strategy 1)

Option for printingOptions changed from normal to all

Presolve 2 (0) rows, 3 (0) columns and 6 (0) elements

Statistics for presolved model

Problem has 2 rows, 3 columns (3 with objective) and 6 elements

Column breakdown:

3 of type 0.0->inf, 0 of type 0.0->up, 0 of type lo->inf,

0 of type lo->up, 0 of type free, 0 of type fixed,

0 of type -inf->0.0, 0 of type -inf->up, 0 of type 0.0->1.0

Row breakdown:

0 of type E 0.0, 0 of type E 1.0, 0 of type E -1.0,

1 of type E other, 1 of type G 0.0, 0 of type G 1.0,

0 of type G other, 0 of type L 0.0, 0 of type L 1.0,

0 of type L other, 0 of type Range 0.0->1.0, 0 of type Range other,

0 of type Free

Presolve 2 (0) rows, 3 (0) columns and 6 (0) elements

0 Obj 0 Primal inf 100 (1)

3 Obj 27.625

Optimal - objective value 27.625

Optimal objective 27.625 - 3 iterations time 0.002

Total time (CPU seconds): 0.00 (Wallclock seconds): 0.00

# ==========================================================

# = Solver Results =

# ==========================================================

# ----------------------------------------------------------

# Problem Information

# ----------------------------------------------------------

Problem:

- Name: unknown

Lower bound: 27.625

Upper bound: 27.625

Number of objectives: 1

Number of constraints: 2

Number of variables: 3

Number of nonzeros: 3

Sense: minimize

# ----------------------------------------------------------

# Solver Information

# ----------------------------------------------------------

Solver:

- Status: ok

User time: -1.0

System time: 0.0

Wallclock time: 0.0

Termination condition: optimal

Termination message: Model was solved to optimality (subject to tolerances), and an optimal solution is available.

Statistics:

Branch and bound:

Number of bounded subproblems: None

Number of created subproblems: None

Black box:

Number of iterations: 3

Error rc: 0

Time: 0.02223515510559082

# ----------------------------------------------------------

# Solution Information

# ----------------------------------------------------------

Solution:

- number of solutions: 0

number of solutions displayed: 0

5.2.4.8. Step 7. Display solution#

Following solution, the values of any Pyomo variable, expression, objective, or constraint can be accessed using the associated value property.

bm.pprint()

1 Set Declarations

S : Size=1, Index=None, Ordered=Insertion

Key : Dimen : Domain : Size : Members

None : 1 : Any : 3 : {'A', 'B', 'W'}

1 Var Declarations

x : Size=3, Index=S

Key : Lower : Value : Upper : Fixed : Stale : Domain

A : 0 : 37.5 : None : False : False : NonNegativeReals

B : 0 : 62.5 : None : False : False : NonNegativeReals

W : 0 : 0.0 : None : False : False : NonNegativeReals

1 Objective Declarations

cost : Size=1, Index=None, Active=True

Key : Active : Sense : Expression

None : True : minimize : 0.32*x[A] + 0.25*x[B] + 0.05*x[W]

2 Constraint Declarations

composition : Size=1, Index=None, Active=True

Key : Lower : Body : Upper : Active

None : 0.0 : 0.0049999999999999975*x[A] - 0.0030000000000000027*x[B] - 0.04*x[W] : +Inf : True

volume : Size=1, Index=None, Active=True

Key : Lower : Body : Upper : Active

None : 100.0 : x[A] + x[B] + x[W] : 100.0 : True

5 Declarations: S x cost volume composition

print(bm.cost())

27.625

print(f"Minimum cost to produce {V} gallons at greater than ABV={C_lb}: ${bm.cost():5.2f}")

Minimum cost to produce 100 gallons at greater than ABV=0.04: $27.62

for s in bm.S:

print(f"{s}: {bm.x[s]():6.2f} gallons")

A: 37.50 gallons

B: 62.50 gallons

W: 0.00 gallons

5.2.5. Parametric Studies#

An important use of optimization models is to investigate how operations depend on critical parameters. For example, for this blending problem we may be interested in questions like:

How does the operating cost change with product alcohol content?

What is the cost of producing one more gallon of product?

What if the supply of a raw material is constrained?

What if we produce two products rather than one?

How much would be pay for raw materials with different specifications

5.2.5.1. Consolidating the model into a single function to create and solve for optimal blend#

To enable parametric studies, our first step is to consolidate the model into a function that accepts problem data and reports an optimal solution.

def blend_beer(data, V=100, C_lb=0.04):

''' Create and solve blending optimization model for beer production

Arguments:

data: pandas DataFrame with columns ['blending stock', 'Concentration', 'Price']

V: float, total volume of beer to produce

C_lb: float, lower bound on alcohol by volume (ABV) of beer

Returns:

bm: Pyomo model object (solved)

'''

# create model

bm = pyo.ConcreteModel('Blending Model')

# create index set for decision variables

bm.S = pyo.Set(initialize=data.index)

# create decision variables

bm.x = pyo.Var(bm.S, domain=pyo.NonNegativeReals)

# specify objective

@bm.Objective(sense=pyo.minimize)

def cost(bm):

return sum(bm.x[s] * data.loc[s, "Price"] for s in bm.S)

# volume constraint

@bm.Constraint()

def volume(bm):

return sum(bm.x[s] for s in bm.S) == V

# composition constraint

@bm.Constraint()

def composition(bm):

return sum(bm.x[s]*(data.loc[s, "Concentration"] - C_lb) for s in bm.S) >= 0

# solve model

# solver = pyo.SolverFactory('glpk')

solver = pyo.SolverFactory('cbc')

solver.solve(bm)

# return model for post-processing and display

return bm

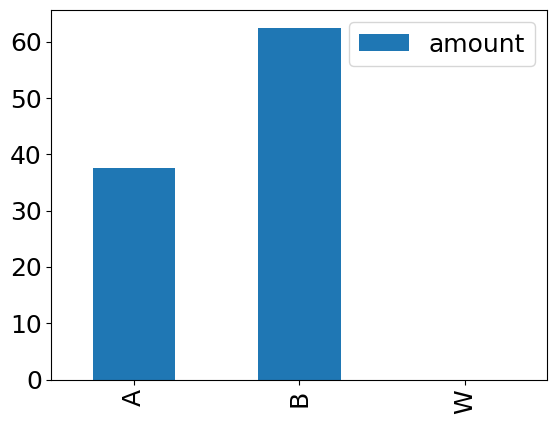

5.2.5.2. How to use the optimization model#

# specify blending stock data

data = pd.DataFrame([

['A', 0.045, 0.32],

['B', 0.037, 0.25],

# ['C', .042, .28],

['W', 0.000, 0.05]],

columns = ['blending stock', 'Concentration', 'Price']

)

data.set_index('blending stock', inplace=True)

display(data)

# set product requirements

volume = 100

abv = 0.04

# compute optimal solution using optimization model

bm = blend_beer(data, volume, abv)

# extract data from the model

optimal_blend = pd.DataFrame()

optimal_blend.index = [s for s in bm.S]

optimal_blend["amount"] = [bm.x[s]() for s in bm.S]

min_cost = bm.cost()

# display solutoin

print(f"Minimum cost to produce {volume} gallons at ABV={abv} = ${min_cost:5.2f}")

display(optimal_blend)

optimal_blend.plot(y="amount", kind="bar", fontsize=18)

| Concentration | Price | |

|---|---|---|

| blending stock | ||

| A | 0.045 | 0.32 |

| B | 0.037 | 0.25 |

| W | 0.000 | 0.05 |

Minimum cost to produce 100 gallons at ABV=0.04 = $27.62

| amount | |

|---|---|

| A | 37.5 |

| B | 62.5 |

| W | 0.0 |

<Axes: >

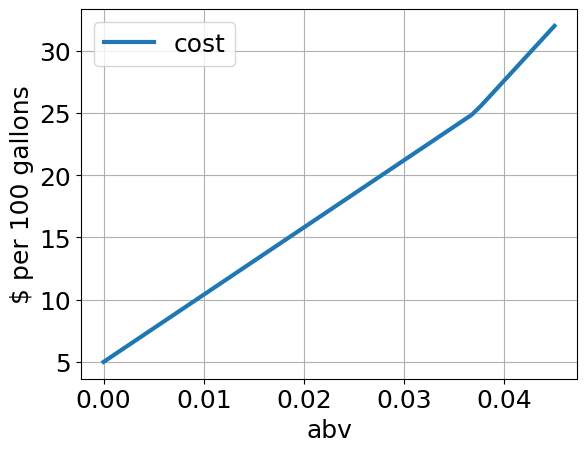

5.2.6. Parametric Study#

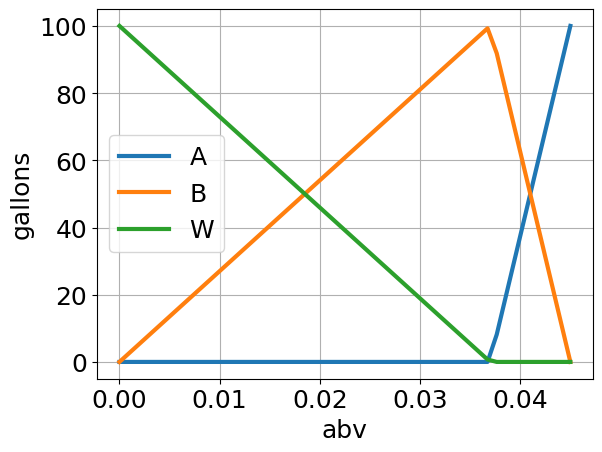

The following cell uses the optimal blending model to compute the minimum cost and blending stocks to produce

print(data)

volume = 100

# gather results for a range of abv values

abv = np.linspace(0, 0.045)

results = pd.DataFrame(columns=["abv", "cost", "A", "B", "W"])

for row, a in enumerate(abv):

bm = blend_beer(data, volume, a)

results.loc[row] = [a, bm.cost(), bm.x["A"](), bm.x["B"](), bm.x["W"]()]

results.plot(x="abv", y="cost", ylabel="$ per 100 gallons", grid=True)

results.plot(x="abv", y=["A", "B", "W"], ylabel="gallons", grid=True)

Concentration Price

blending stock

A 0.045 0.32

B 0.037 0.25

W 0.000 0.05

<Axes: xlabel='abv', ylabel='gallons'>

5.2.7. Study Exercises#

5.2.7.1. Exercise 1#

An additional raw blending stock “C” becomes available with an abv of 4.2% at a cost of 28 cents per gallon. How does that change the optimal blend for a product volume of 100 gallons and an abv of 4.0%?

5.2.7.2. Exercise 2#

Having decided to use “C” for the blended product, you later learn only 50 gallons of “C” are available. Modify the solution procedure to allow for limits on the amount of raw maaterial, and investigate the implications for the optimal blend of having only 50 gallons of “C” available, and assuming the amounts of the other components “A”, “B”, and “W” remain unlimited.

5.2.7.3. Exercise 3#

An opportunity has developed to sell a second product with an abv of 3.8%. The first product is now labeled “X” with abv 4.0% and sells for $1.25 per gallon, and the second product is designated “Y” and sells for $1.10 per gallon. You’ve also learned that all of your raw materials are limited to 50 gallons. What should your production plan be to maximize profits?